|

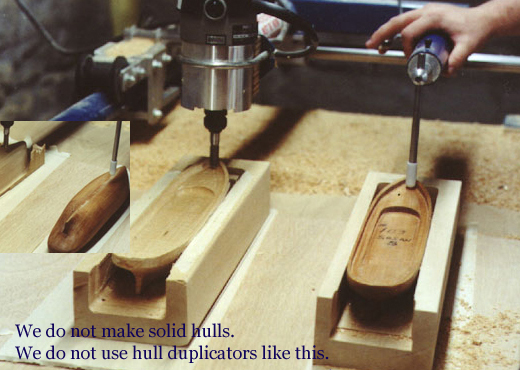

We at Model Ship

Master craft model ships one by one.

For the hull, instead of using machinery to

carve wood blocks into multiple units simultaneously, we use thin, narrow stripes

on frames just like how real

ships’ hulls are built. An example of this

technique can be viewed here:

hollow hull ship. And instead of

using balsa wood that is as soft as paper, we use

hard

wood such as teak, rosewood, ebony, jupiter...

Carved hulls from

solid block of wood makes ship models extremely

heavy. A three-foot long ship can sore a man's

arms within few steps and a

five-foot one requires two porters. Those

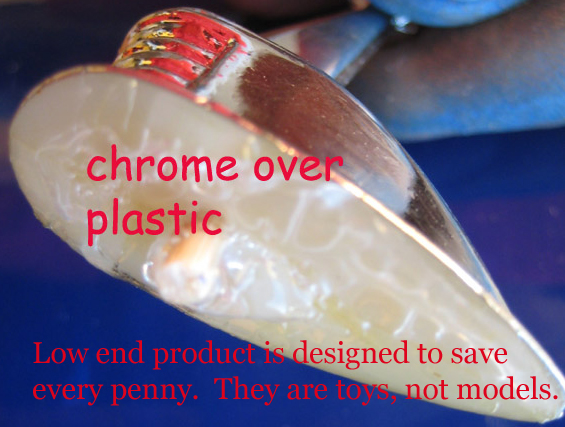

model ships might look quite good due to computer

printed decal application but are in fact are more like

children toys than art. Think of this as real

cutout windows versus dark decal. The

decals are also prone to degradation over time.

Model Ship Master

believes in the value of the materials that make up

the product and thus avoid the techniques that hide the inferior materials

beneath the model's surface.

Below are some

examples of the bad products that might look good

from the outside.

|